-

Mixed Cellulose Ester | CAB Resin Supplier Alternative for Eastman

CAB 381-0.1 Cellulose acetate butyrate is a cellulose ester with medium butyryl content and low viscosity. This type of CAB resin is recommended for applications requiring low application viscosity and relatively high solids content.Hot Tags : CAB-381-0.1 Mixed Cellulose Ester cellulose acetate butyrate cab eastman cellulose acetate butyrate cab eastman resin cab

Read more -

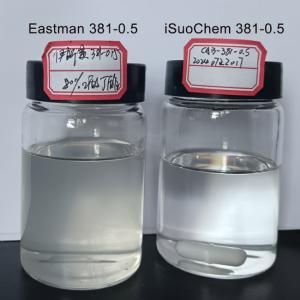

Free Sample/TDS/SDS Celulose Acetate Butyrate cab 381-(0.1/0.5/2/20) 551-(0.01/0.2) 531-1 Alternative for Eastman

iSuoChem CAB resin can be alternatives for EASTMAN CAB full series.Hot Tags : Celulose Acetate Butyrate cab cab resin 381-0.5 cab cellulose butane powder cellulose acetate butyrate price eastman cab cab 381 20 tds

Read more -

China Wholesale Cellulose Acetate Butyrate CAB Resin Price for sale

Best Price and Best quality cellulose acetate butyrateHot Tags : celulose acetate butyrate cab 381 2 cab cellulose butane cab cellulose butyrate cab resin price cabcellulose butyrate

Read more -

Acetylated Cellulose Acetate Butyrate CAB Ester Butanoate Butyric acid Ester Resin

(CAB) Cellulose acetate butyrate is a mixed cellulose ester with high(or medium) butyryl content and high(or low) viscosity.Hot Tags : Cellulose Acetate Butanoate acetylated cellulose butyric acid ester Cellulose Acetate Butyric acid ester cellulose Cellulose Acetate Butyrate Resin

Read more -

iSuoChem CAB Resin Replaces EASTMAN CAB for Industrial/Autumotive Paint manufacturers

EASTMAN CAB Resin can be perfectly replaced by our CAB Series. CAB resins can effectively solve the problems encountered in Industrial/Autumotive Paint manufacturering process.Hot Tags : CAB for Automotive Paints CAB for Industrial Paints iSuoChem CAB Resin EASTMAN CAB for Industrial Paint

Read more -

Plastics Additives | Select Suitable Additives for Plastics

Plastic additives are special ingredients added during the production of plastics to improve the performance or processing characteristics of the material. They can adjust key indicators such as the hardness, strength, and heat resistance of plastics, making the base polymer have a wider range of application value. These additives are usually not used in large quantities, but they can significantly change the final performance of the plastic, allowing the same base material to meet the needs of different uses from flexible packaging to engineering components. Common additives include: plasticizers (to improve material flexibility), flame retardants (to enhance fire resistance), antioxidants (to prevent aging and degradation), lubricants (to improve processing fluidity) and fillers (such as calcium carbonate, used to reduce costs or increase hardness).Hot Tags : Additives for Plastics

Read more

English

English français

français русский

русский español

español português

português العربية

العربية 한국의

한국의 ไทย

ไทย Tiếng việt

Tiếng việt Indonesia

Indonesia