The application background of powder coatings in the automotive industry

iSuoChem Marketing Department / Edited by Jason

In 2024, it will be the tenth year that China's new energy vehicles have become the world's number one. Since 2015, China's new energy vehicle development has been "galloping all the way" and has ranked first in the world's new energy vehicle sales for 9 consecutive years. At the same time, the models and products are constantly enriched. From January to May 2024, my country's new energy vehicle production and sales reached 3.926 million and 3.895 million respectively, an increase of 30.7% and 32.5% year-on-year, and the market share reached 33.9%, which can be said to be a "rising voice".

Under the dual carbon goals, the low-carbon value of new energy vehicles is greater than you think

As a representative industry of green and low carbon, new energy vehicles have been branded with low-carbon and environmental protection since their birth. Not only is the design, development and production of new energy vehicles the focus of energy conservation and carbon reduction, but the level and quality of their coating process are also of great concern. Today, we can see that powder coating technology, as a supporting industry for new energy vehicles, is developing rapidly. They not only coincide with the goals of the automotive industry to reduce carbon footprint and reduce environmental burden, but also show strong vitality in the market.

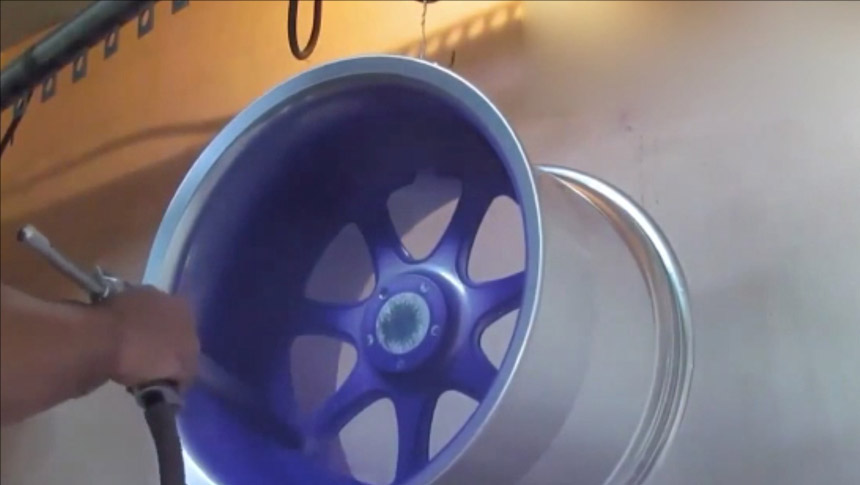

It is estimated that a typical car is assembled from more than 20,000 parts. Special cars with extremely complex structures, such as Mercedes-Benz, BMW, Audi, etc., can have as many as 30,000 independent parts. Powder coatings can effectively reduce friction between auto parts and auto accessories, and reduce energy consumption. In automobile manufacturing, car batteries, wheels, frames, under-hood parts (such as shock absorbers and radiators), car bodies and various parts (joysticks, mirrors, wipers and horns, etc.) are all coated with powder coatings.

As a representative of environmentally friendly coatings, powder coatings have been exploring the development of the automotive industry. At present, they are widely used in some commercial vehicle bodies and auto parts, as well as motors, battery systems and electrical storage units, and are actively trying to develop them in car bodies and future super-lightweight car platforms.

Powder coatings have been used in industry for nearly half a century. In the early days, due to factors such as high curing temperature, long color change time, difficulty in filming, and poor decorative properties, they could not be promoted and applied in automotive spraying. With the advancement of powder coating manufacturing technology and coating technology, some of the above problems have been effectively solved. Powder coatings continue to replace liquid coatings in some fields and extend to the automotive industry.